Application Background

In high-performance electronics such as laptops, servers, 5G communication devices, and AI accelerators, packaging structures are becoming increasingly complex, with higher component density and faster data processing.

Coplanarity is a critical assembly parameter that directly impacts electrical connectivity, thermal performance, and product lifespan.

Measurement Challenges

In high-density packaging, closely spaced solder joints are prone to occlusion. Traditional 3D line-scan systems often suffer from blind spots due to projection angle limitations;

Repeatability must be within ±2 μm to ensure consistent and reliable results;

In mass production, measurement cycle time must be less than 8 seconds per part.

Solution Highlights

FPGA-Based Imaging Acceleration

Industrial-grade parallel processing with per-frame speed as fast as 0.14 seconds for high-throughput inspection.

Multi-Projection Structured Light Technology

Multi-angle projection eliminates shadows and occlusions, enabling full coverage of pins and solder pads.

Large Field of View with Micron-Level Precision

16.2MP CMOS sensor with 6μm pixel pitch, covering a 53×30.2×20mm³ measurement volume; repeatability < 0.1μm for detecting subtle warping and non-coplanarity.

Telecentric Optics + Combined 2D/3D Measurement

Minimizes angle-related distortion and ensures consistent measurement; pixel-level alignment of 2D textures and 3D point clouds for precise structural reconstruction.

Customer Benefits

Enables blind-spot-free inspection of high-density packages, ensuring reliable solder connections;

Enhances early detection of coplanarity anomalies to prevent cold soldering and thermal failures;

Supports high-speed production lines, improves yield, and optimizes process control.

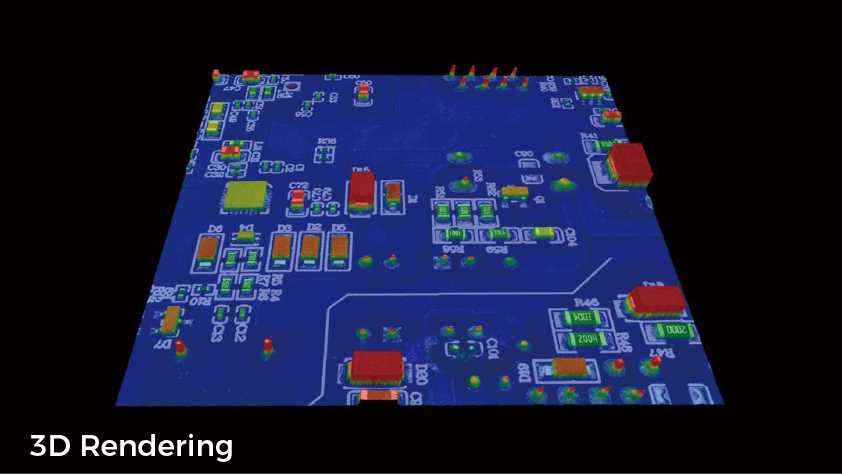

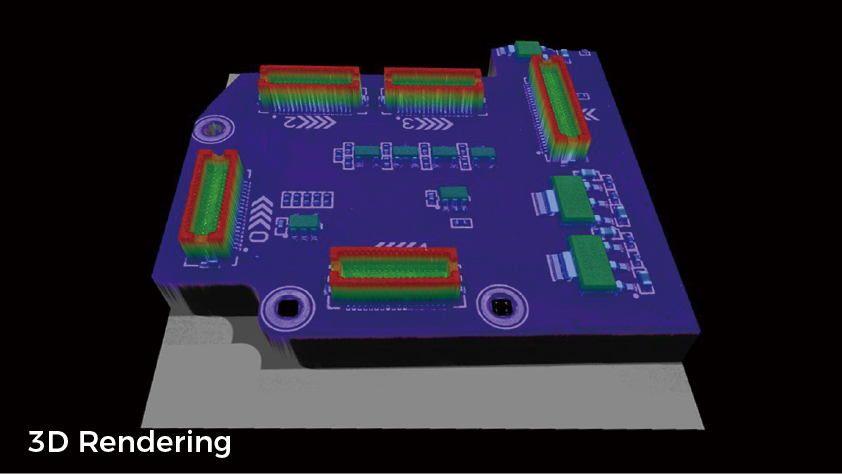

3D Point Cloud

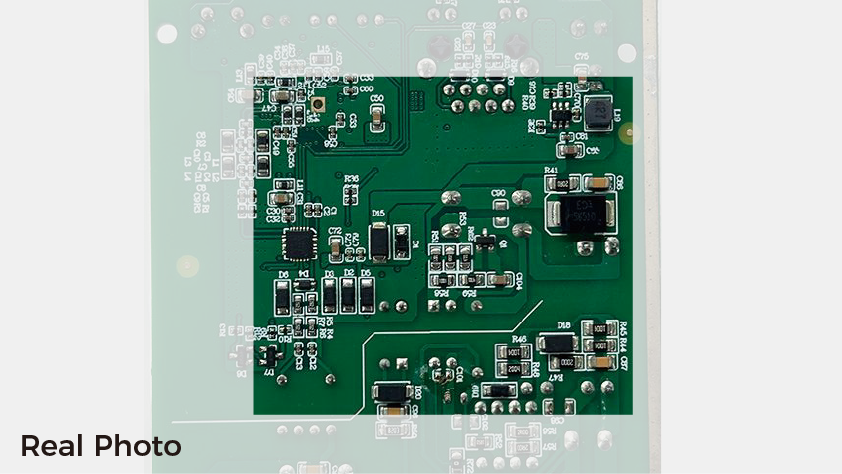

PCBA BOARD

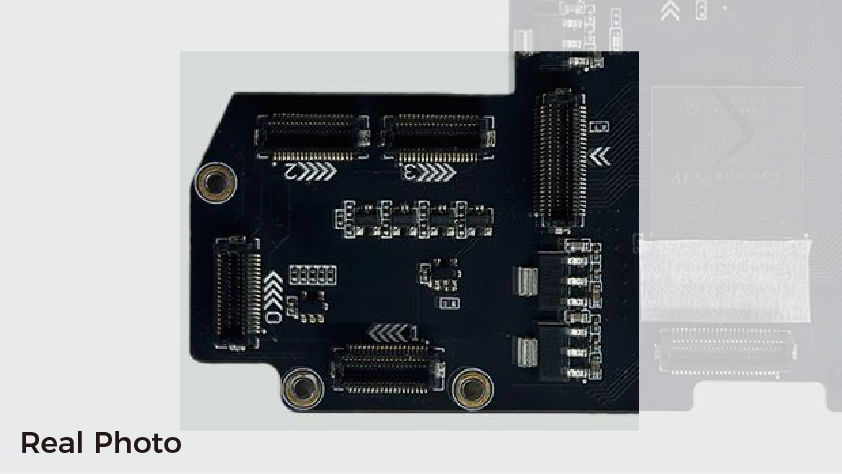

PCBA BOARD

© All images sourced from Mega Phase cameras. Unauthorized replication or misuse is subject to legal claims.